The Results

We found that dynamically synchronizing machine speeds across a production line maximized mean-time-between-failure (MTBF), eliminating 60.5% of unplanned downtime and optimizing Overall Equipment Effectiveness (OEE).

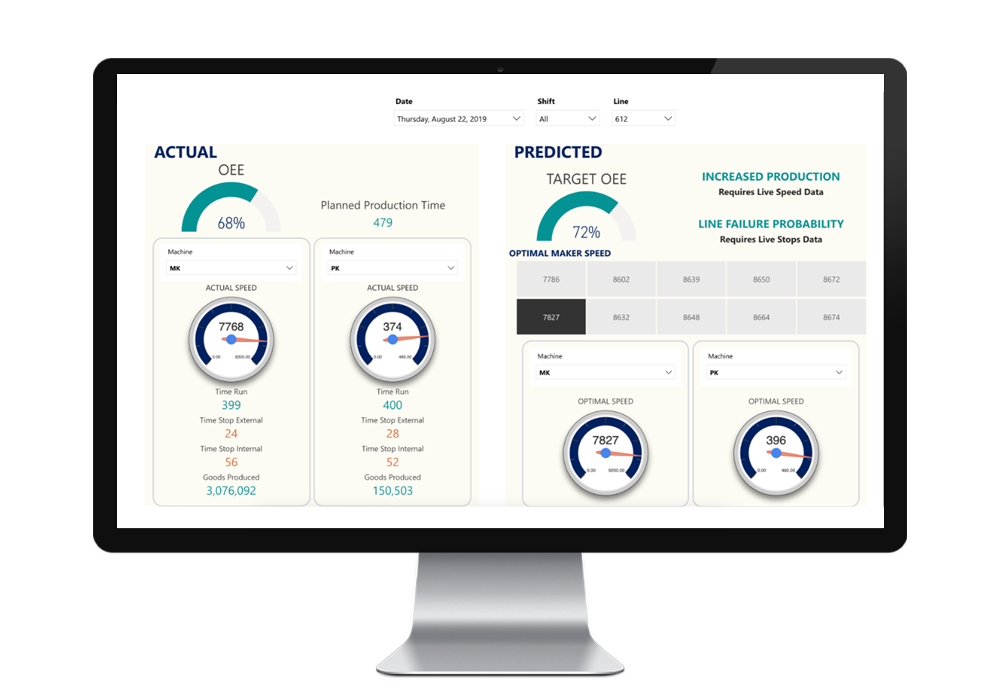

Informed Insights provides real-time Maker and Packer optimal speed predictions with visibility into the anticipated effect of each potential change.

- Failure probability (Risk to Process) of implementing new speed

- Projected increased production potential

- Target OEE given real-time line and shift conditions